Blog / Wiring (12V)

Posted on 28 February 2015 at 01:33 am (CET)

Posted on 28 February 2015 at 01:33 am (CET)

I continued again solving the problems that I still had.

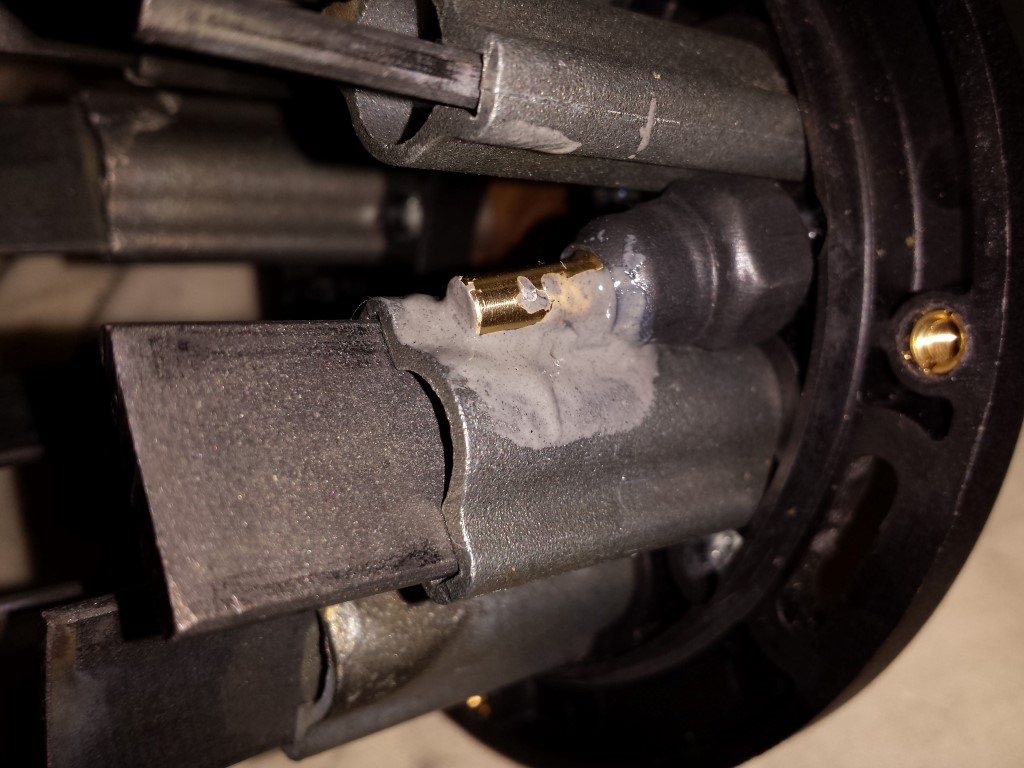

I was able to place the temperature sensor of Trailtech in the motor, attached it with JB Weld, will be stuck on there forever. Also tested it already and it seems to work well. Will find out on the next test ride if it really works properly.

I tightened all of the nuts in the motor again and added Loctite inbetween. Then I placed another nut on all of the nuts that are holding the connection points of the motor and the carbon brushes, again with Loctite. I don't really expect this to come loose again. Also lengthened the wires for the temperature sensor.

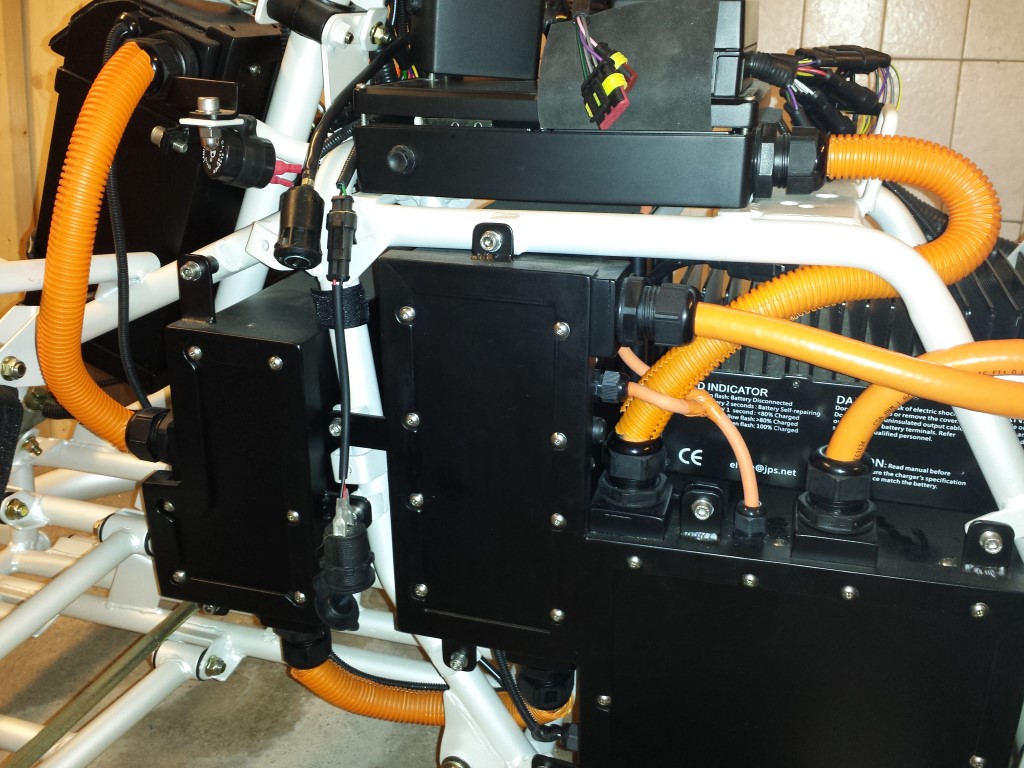

After that I placed the motor back on the quad bike again and connected the orange wires in a better way. They have a lot more play now with suspension travel of the rear swingarm, should be almost no pressure anymore on the connection points of the motor.

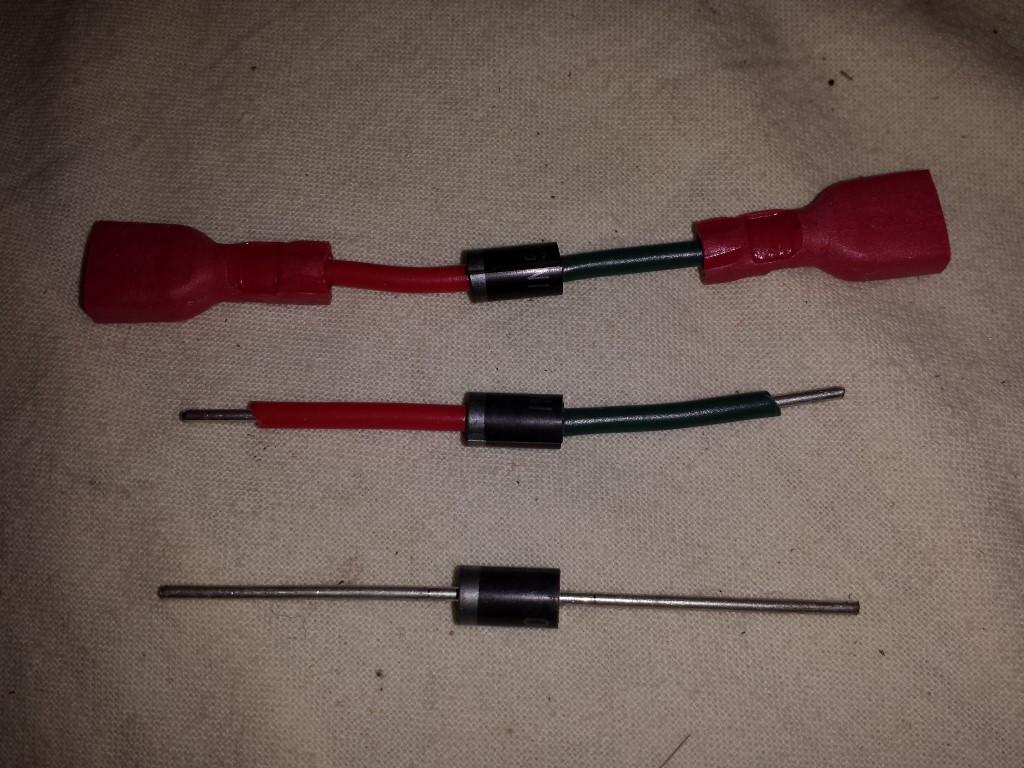

I noticed that there were big sparks between the contacts of the small 12 V relays when disengaging the contactors. I used some diodes for this, the contactors open a bit slower now but at least there are no more sparks anymore in the relays. Don't want to keep replacing the relays when they break.

Also added a capacitor and resistor so the contactor between the battery packs uses less power, now it doesn't get so warm anymore.

On the contactors for forward and reverse I only used the diodes since these won't be engaged for such a long time, heat won't be an issue here.

I've now fixed all of the problems that I ran into. Hopefully there won't be more coming soon since I really want to go the RDW this coming month for the road approval test. But before I go there I want to test at least once more. Tomorrow the weather would be nice and the quad bike is rideable again so I already charged the batteries a bit. ;)

Posted on 26 February 2015 at 12:42 am (CET)

Posted on 26 February 2015 at 12:42 am (CET)

Apparently I hadn't found all problems yet that arised after the test ride. I'm glad I found them now though or the next test ride probably wouldn't have gone so well. For pretty much all of the problems I had to buy these few things.

A few bolts of the front swingarms had come loose. I didn't put any Loctite on them just yet since I wasn't sure how tight they should be. I suddenly saw that there was some space inbetween, that's never good. So I loosened them all, put some Loctite inbetween and tightened them again. Should not come loose anymore now unless I really want to myself.

On the rear something also came loose, the 2 big nuts that keep the sprocket adapter stuck to the rear axle. Because of this the sprocket adapter was ale to move freely on the axle. I did already tighten this with blue Loctite inbetween but apparently that was not strong enough for the forces it has to endure. Also noticed that there was some play between the sprocket adapter and the axle. So I first used Loctite Quick Metal to fill up the space. Then I used red Loctite again to tighten the nuts. This should also not come loose anymore.

After that I continued again with the orange wire hoses. It's pretty hard with these thicker wires, especially the bends. It also still barely fits between the mounts.

On the side of the controller I already placed the RFI filters to reduce noise, also neccessary again for the road approval test at the RDW.

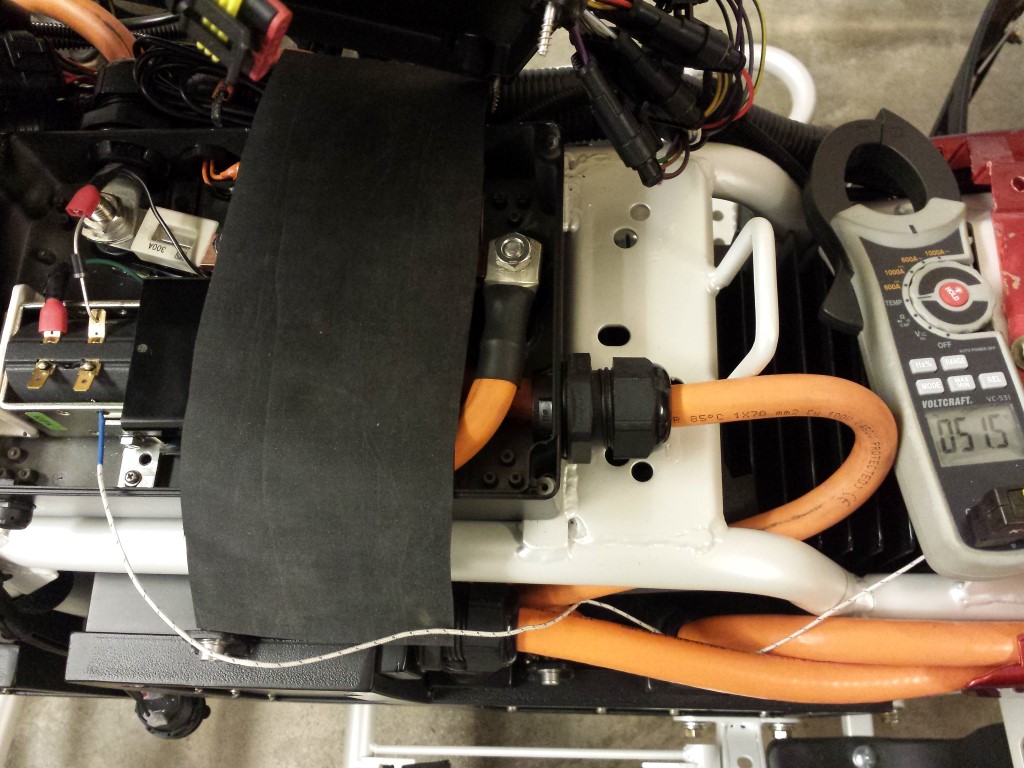

While I was busy with the wire hoses on the wires that go to the motor I suddenly discovered a very big problem. I noticed that there was some play on the connection points of the motor. I immediately took off the protective cover to see what was going on. To my surprise I saw that literally all of the nuts inside were loose. So the connections to the carbon brushes were also all loose. This is something that should never happen, If I would've pushed full power through the motor something would've certainly gone wrong. You can't really see it on the picture but really all of these nuts were loose.

The cause of this is very simple, it's because of the stiff orange wires that didn't have enough space during suspension travel of the rear swingarm. Will have to completely change this because like this there will be too much pressure on the connection points of the motor. I'm first trying to place the wires in a straighter line to the connection points and not all the way through the frame anymore. I will also tighten all of the nuts with Loctite so these hopefully never come loose again.

But ofcourse I couldn't easily reach it anymore so unfortunately I had to take the motor off the quad bike once again. Thankfully this is still pretty easy to do, I really only have to jack it up and remove the suspension. Can just take out the motor together with the motor plate after that.

Since I have the motor out now anyway I also checked if I could replace the temperature sensor with the one from Trailtech. That way I can be sure that I get to see the right temperature on my display. I'm just not really sure yet how I'm going to attach it and if I can even use this sensor this way. Will have to contact the supplier of the motor again for this.

I hope that these were the last few problems for now. It's not really fun to discover these things knowing that the quad bike is almost all finished. But on the other hand it's definately better to see it now than when it's too late.

Posted on 19 February 2015 at 12:03 am (CET)

Posted on 19 February 2015 at 12:03 am (CET)

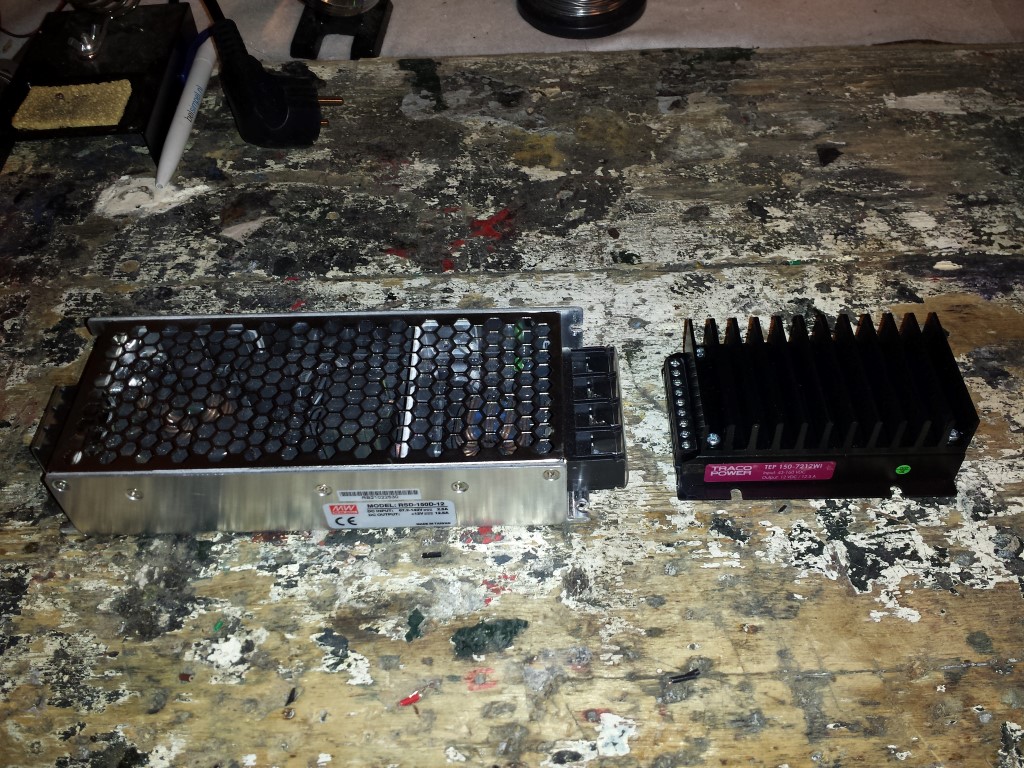

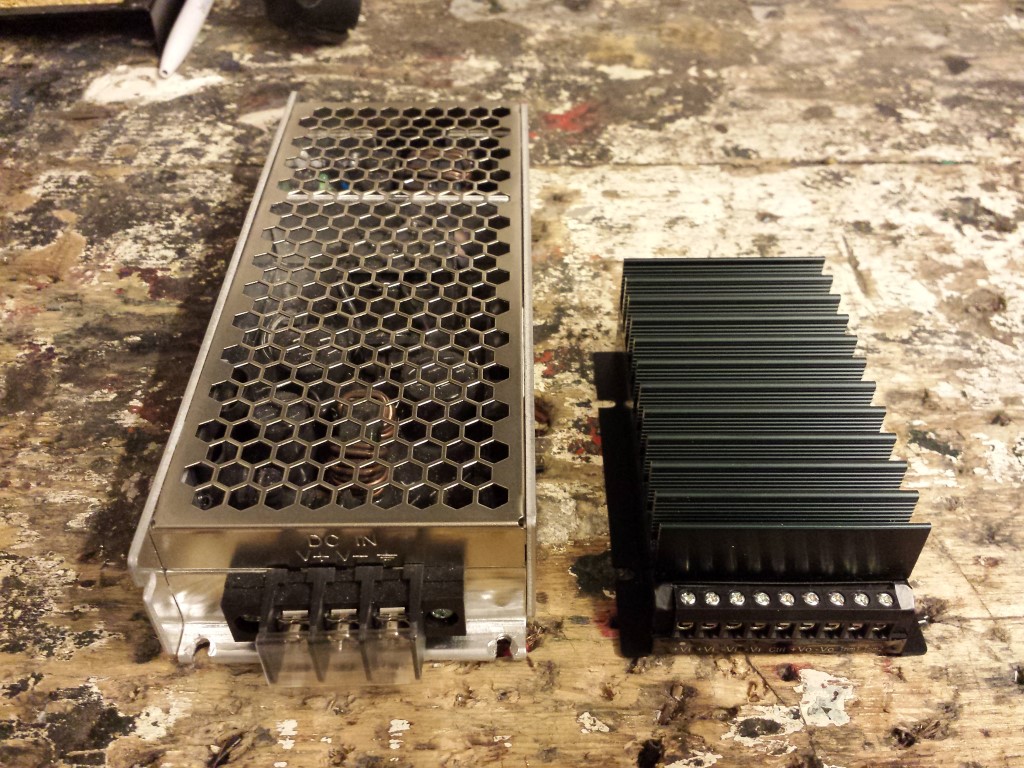

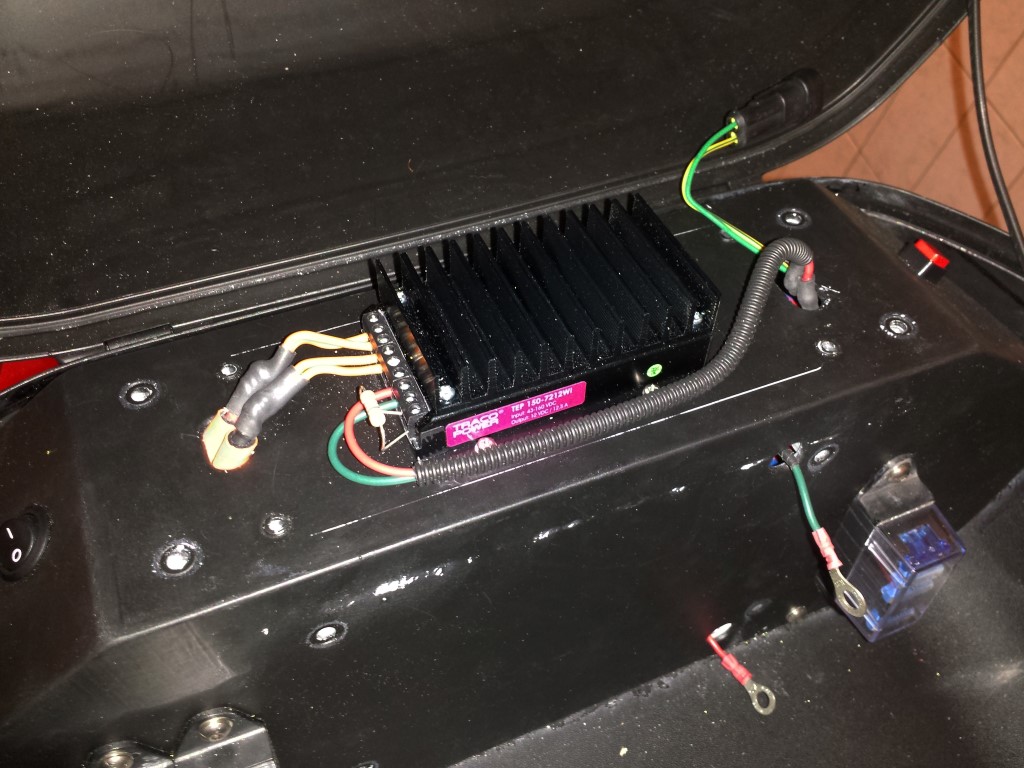

Seeing as a few things have broken during the test ride I've already had to do some repairs. The most important is the DC-DC converter. Ofcourse it was just out of warranty, already bought it a bit longer than 2 years ago so getting it replaced wasn't possible anymore. But I already wasn't satisfied with it since the output voltage was too low (11,9 V). So I bought a different one now, a Traco Power TEP 150. Same power, bigger input range, better isolated and an adjustable output voltage. Unfortunately it was a bit more expensive but for this price I don't think there's a better one. One more difference, it's a lot smaller.

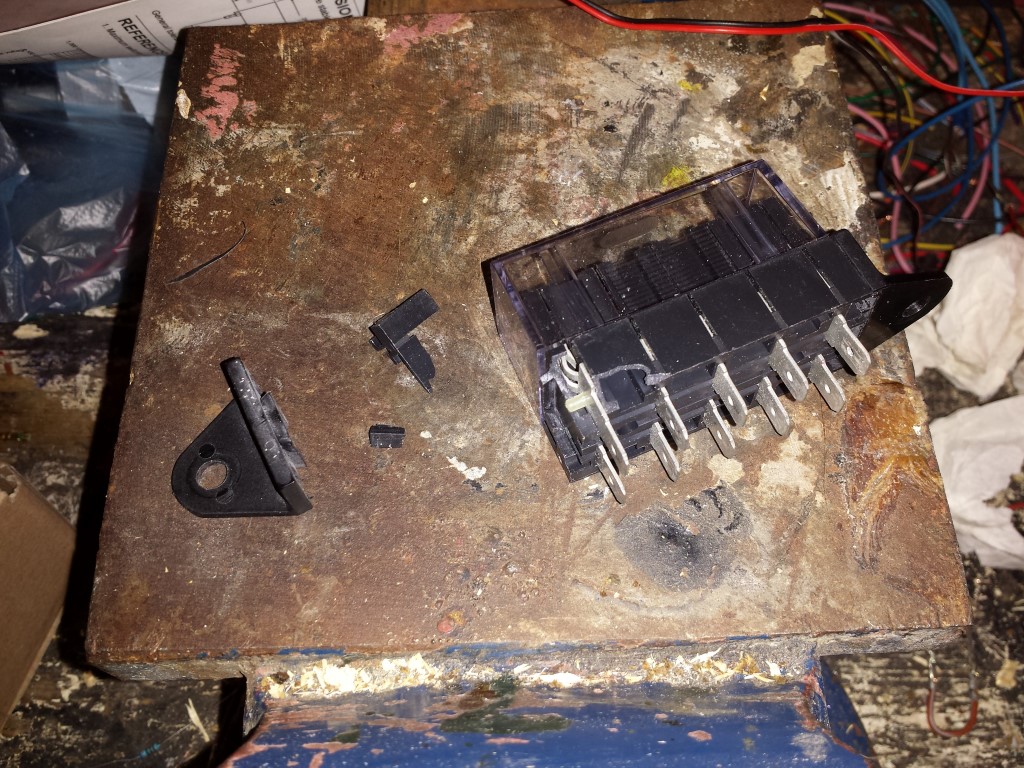

A fusebox also broke because of the heavy 12 V battery I placed in the top case during the test ride.

Replaced it and lengthened the wires for the new DC-DC converter.

And here it's all connected. It also has the option to turn it on and off with a 12 V signal but for now I'll leave it always on.

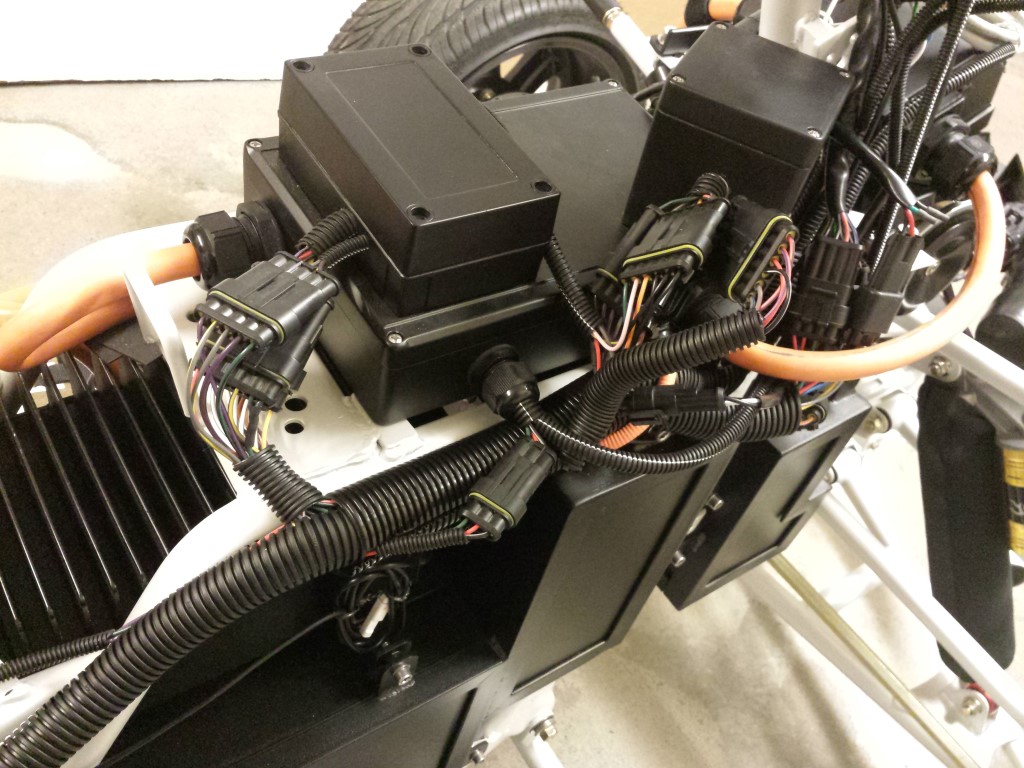

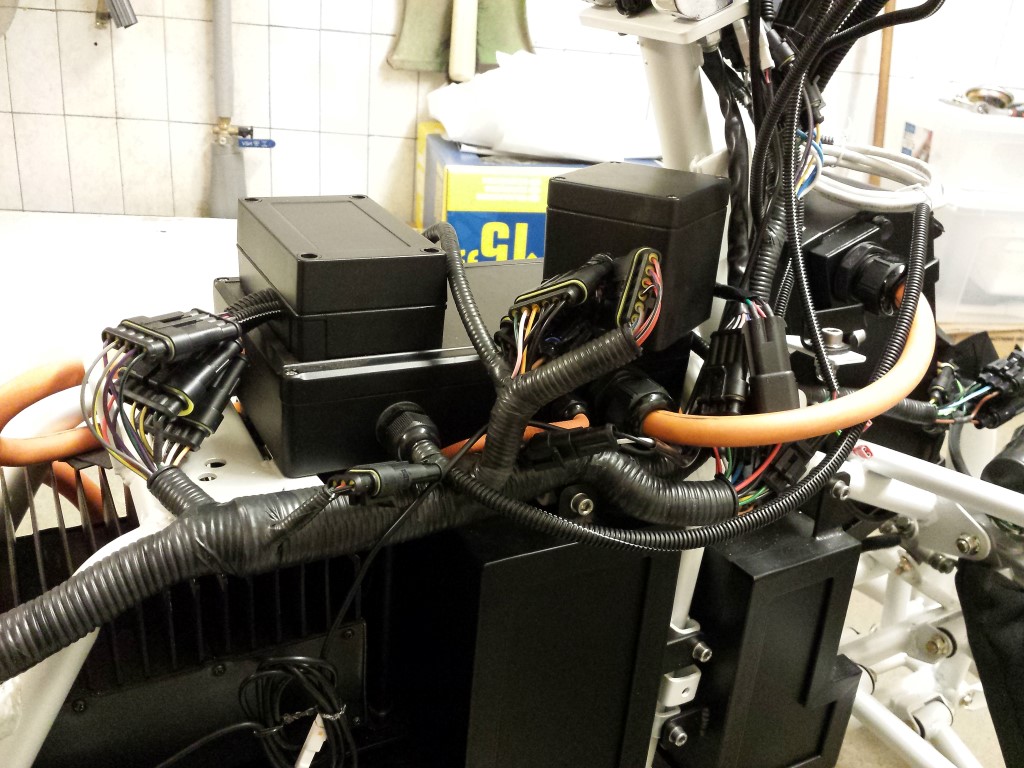

Then something I forgot about. Before the test ride I still wrapped the whole wire harness with wire hoses. Quite a lot of work with so many wires coming together.

After that I put tape all around it.

And placed it back again. Think it looks pretty nice like this.

Currently working on putting wire hoses on all of the orange wires as well. It's for added safety and probably necessary again for the road approval test at the RDW.

The only 2 problems I still have right now are a contactor that's getting quite warm and not getting the temperature sensor in the motor to work with my Trailtech display. For this sensor I still have to contact Trailtech to see if there's a way to calibrate.

As for the contactor I've already contacted the supplier and for now they say that this is normal. Just still have to give them the complete part number so they can confirm it. But most likely it's working just fine, I just still think it's getting too warm myself. Still have to find a solution for this so it gets less warm. It now goes up to about 51,5 degrees celcius with an opened enclosure. With the enclosure closed it'll probably go up to about 70-80 degrees celcius. For the contactor itself this might not be a problem but for the other components that I've placed in the same enclosure it might.

That's about it again. Hopefully I can solve these last few things quickly so I can already make the second test ride at real full power very soon.

Posted on 12 January 2015 at 06:35 pm (CET)

Posted on 12 January 2015 at 06:35 pm (CET)

It's time for another new update.

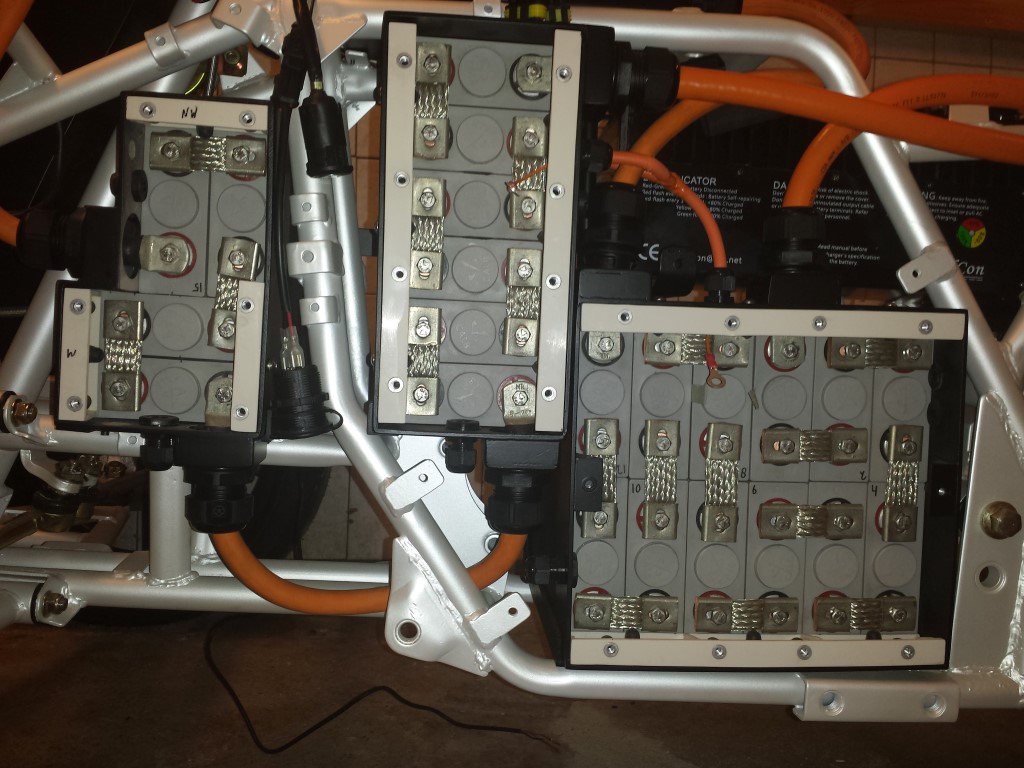

The past few days I've been busy connecting all of the battery cells to eachother. It all went well, for extra safety I already isolated all of the tools with some tape. For the rest you just have to stay very focused.

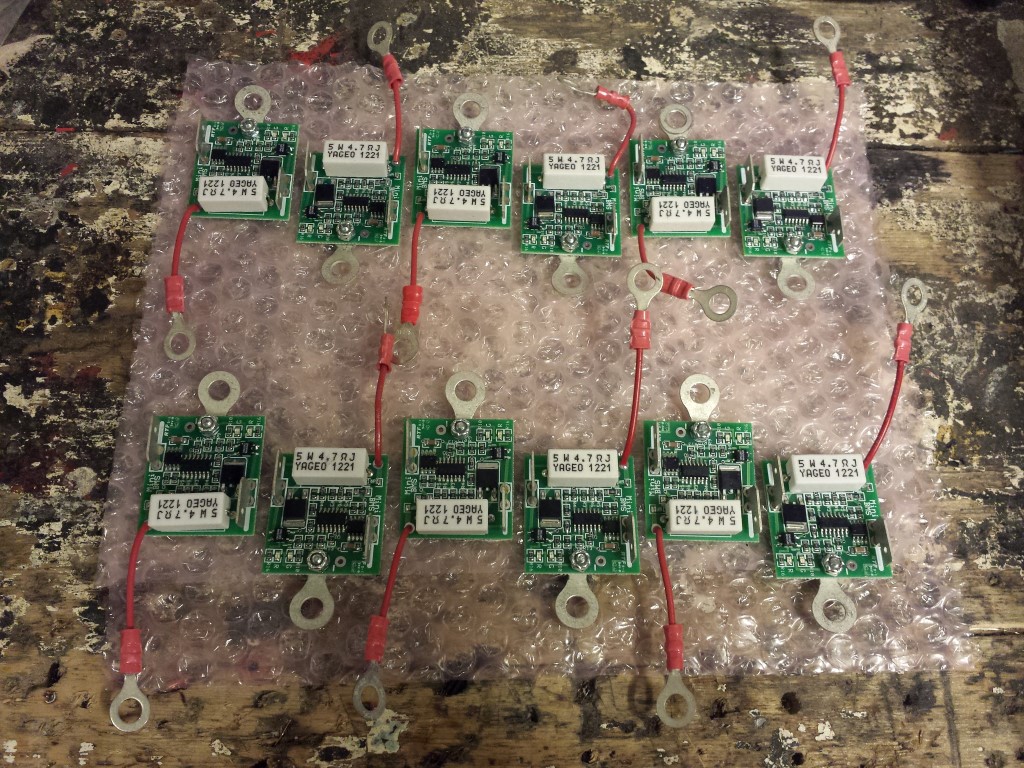

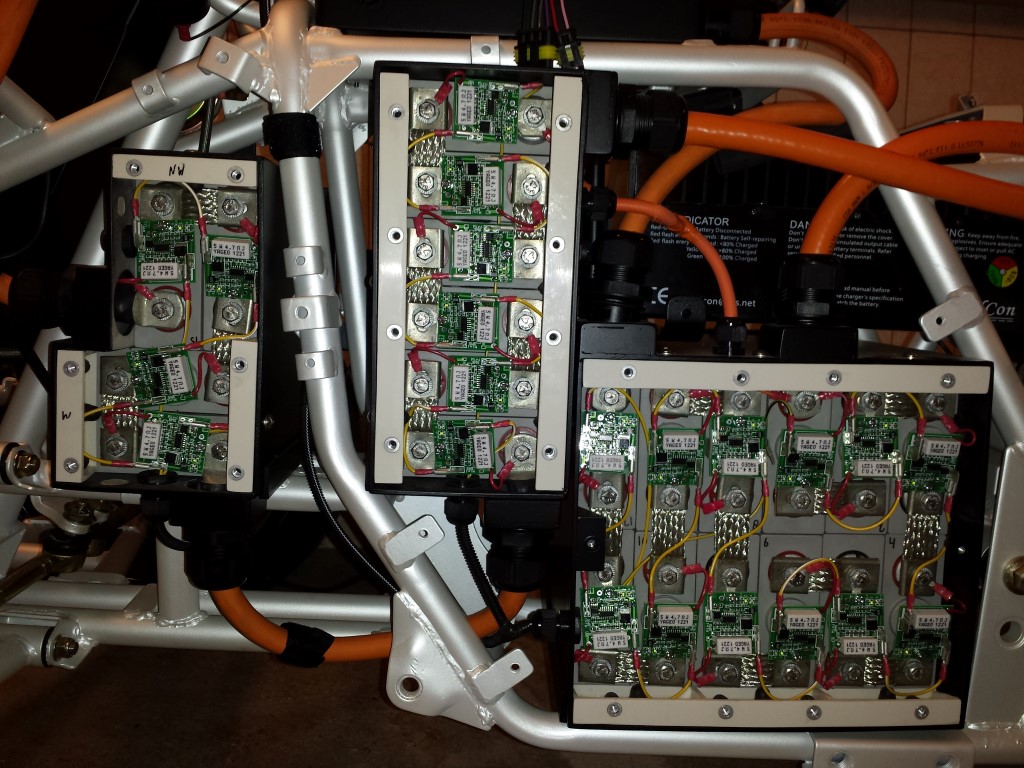

But that's not all yet, I also started on the BMS (Battery Management System).

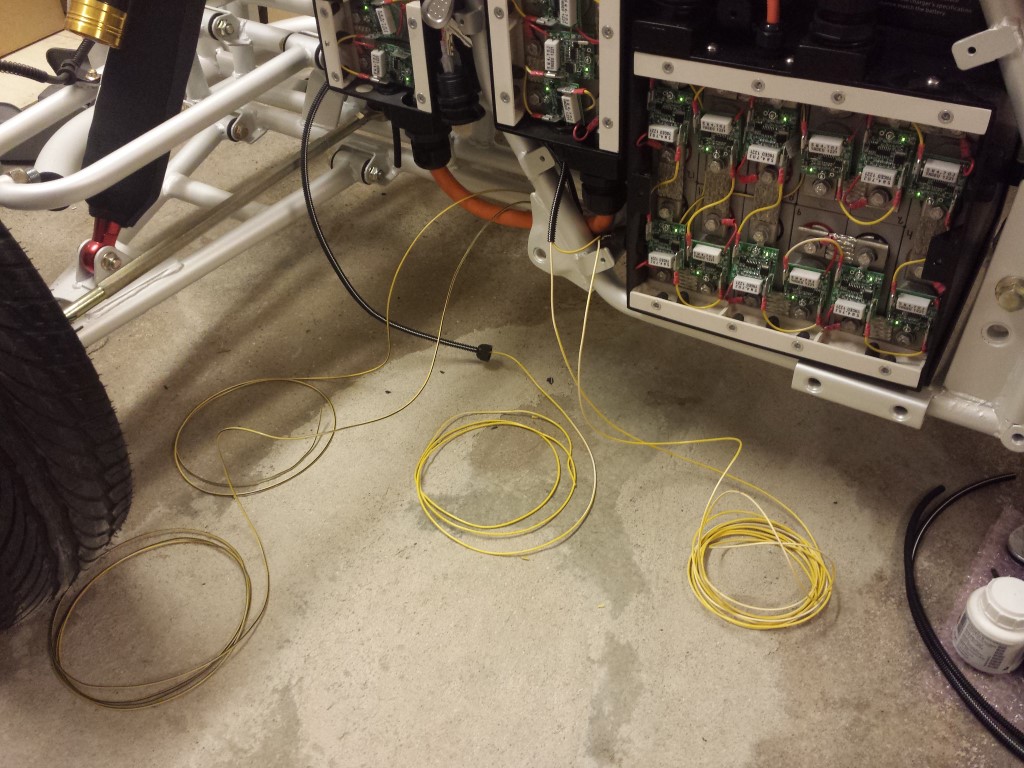

First I made all of the wires exactly to size.

Then I connected them all to the battery cells and to eachother. Thought it'd be a lot of work but it wasn't all that bad. It was the first time something actually took less time than I expected, usually it always takes longer. They're also connected inbetween the battery boxes, this was actually the hardest since at one part I had to push 4 wires through that wire loom. The size I used actually is for only 3 wires. But it all went fine anyway.

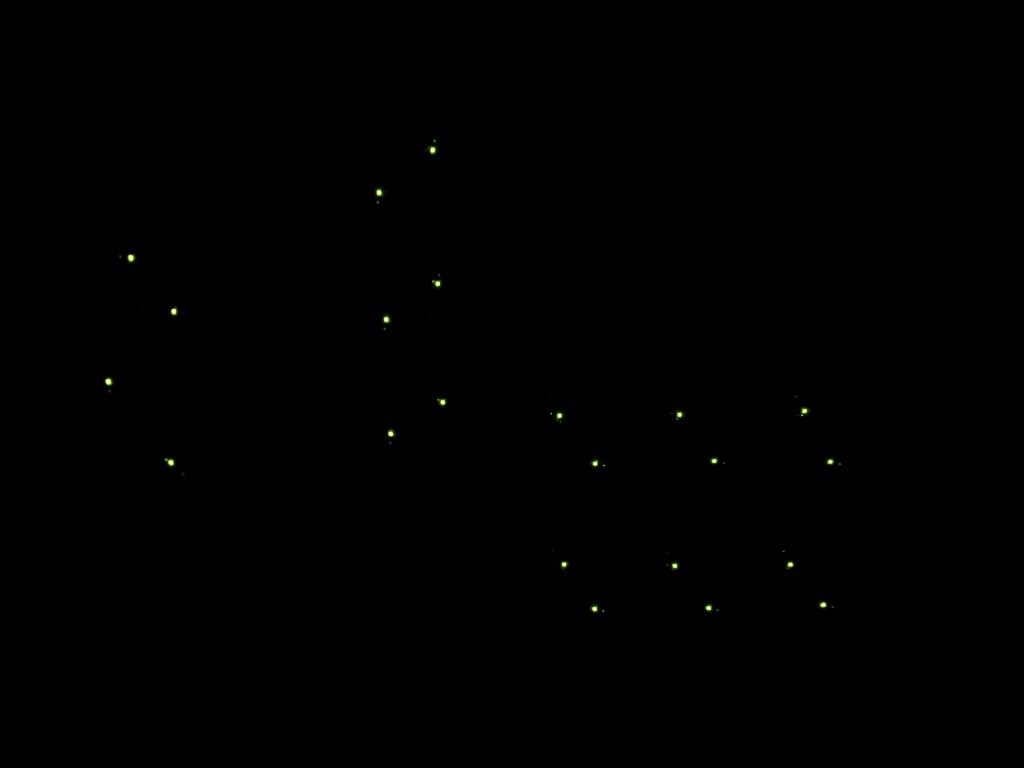

Looks pretty nice too. The green LED's show that they're connected properly and that the battery cell is at the right level.

In the dark it also looks nice with all of those LED's. Just too bad that you won't see any of it anymore once the battery boxes are closed.

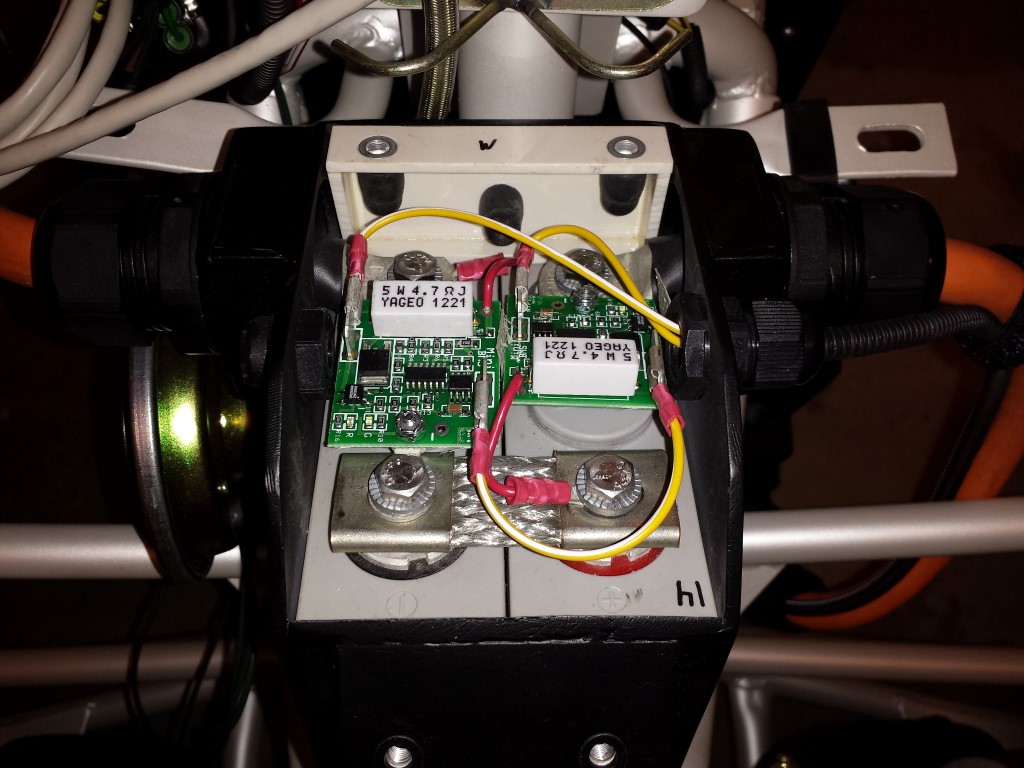

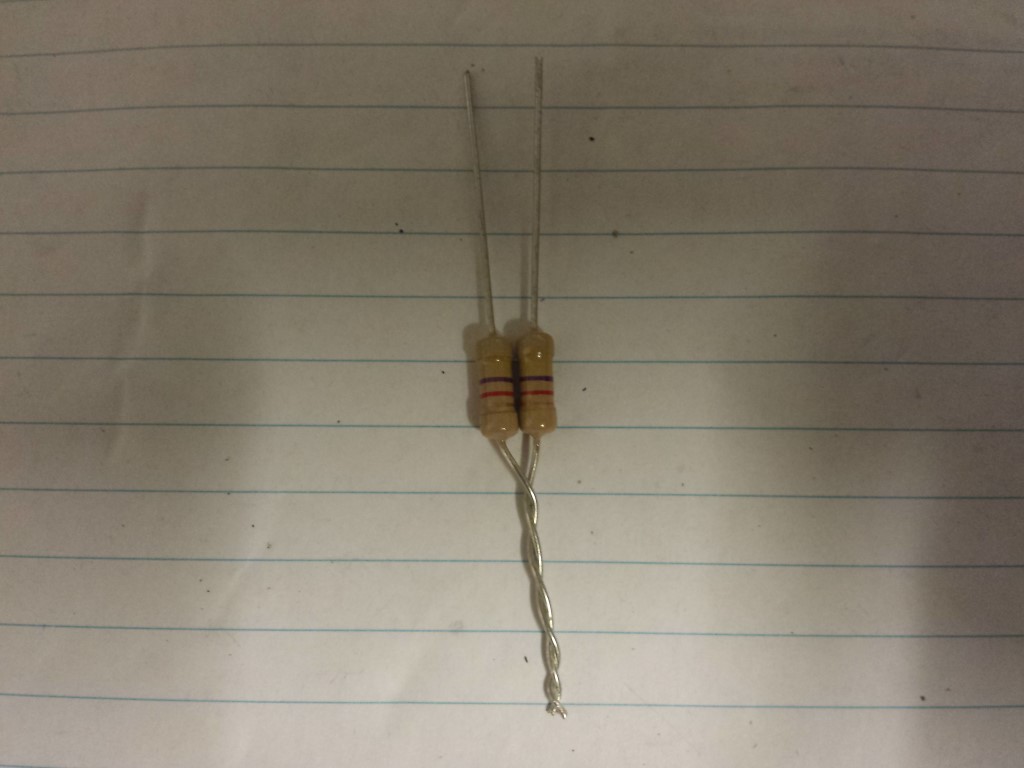

I also connected the throttle now. I used 2 resistors for this and one extra wire, these are again for the BMS. These will make sure that there's not much power available anymore once the battery cells drop below a certain level. This way you won't immediately destroy the battery cells while still being able to get off the road safely.

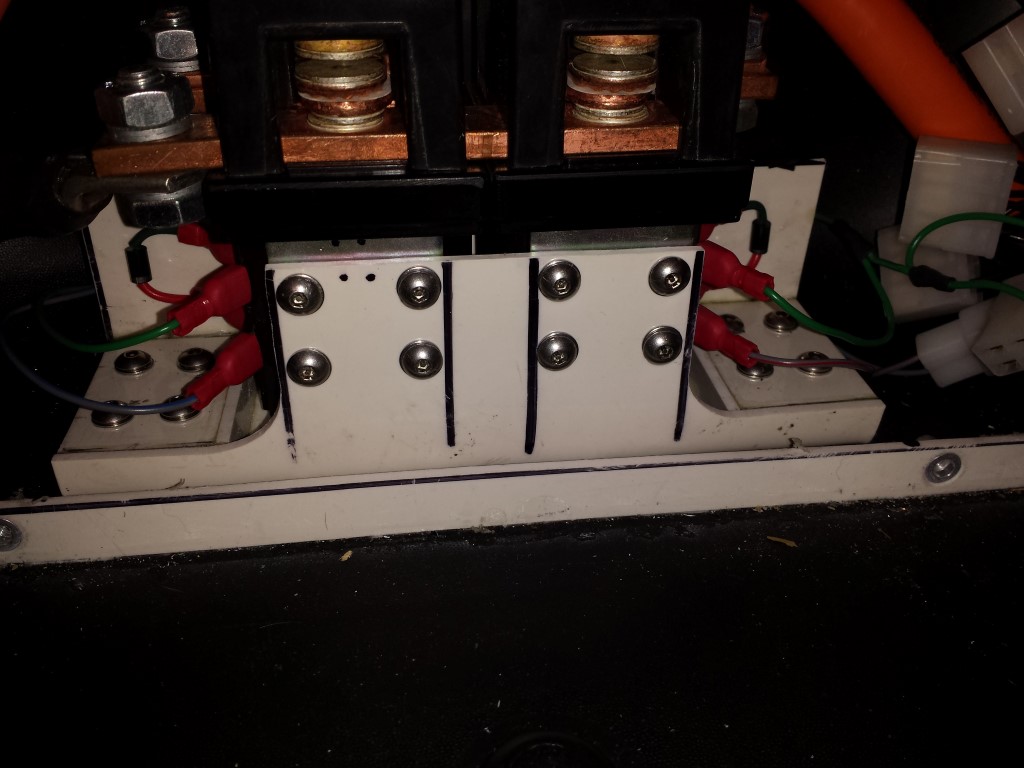

Also placed all of the fuses to be able to test the 12V system. Meanwhile I've already broken one and replaced it, apparently the contactors needed a little more power.

And I can already say that the 12V system is working perfectly. I just had to make a small modification with a relais, for the rest everything seems to be fine. I just have a weird problem where the controller sometimes doesn't give any power the motor after I let it run in reverse and then forward again. Could be that there's just not enough voltage since everything was connected to a 12V battery. Just have to connect the wires to the controller again and then I can try with almost 80V, see if it works better then.

Posted on 5 January 2015 at 01:43 am (CET)

Category: Wiring (12V), Wiring (HV)

Posted on 5 January 2015 at 01:43 am (CET)

Category: Wiring (12V), Wiring (HV)

First off I'd like to wish all readers a happy new year. Hopefully 2015 will be a very good year for all of you.

The first update this year and it already starts good. I was able to completely finish the top case this weekend.

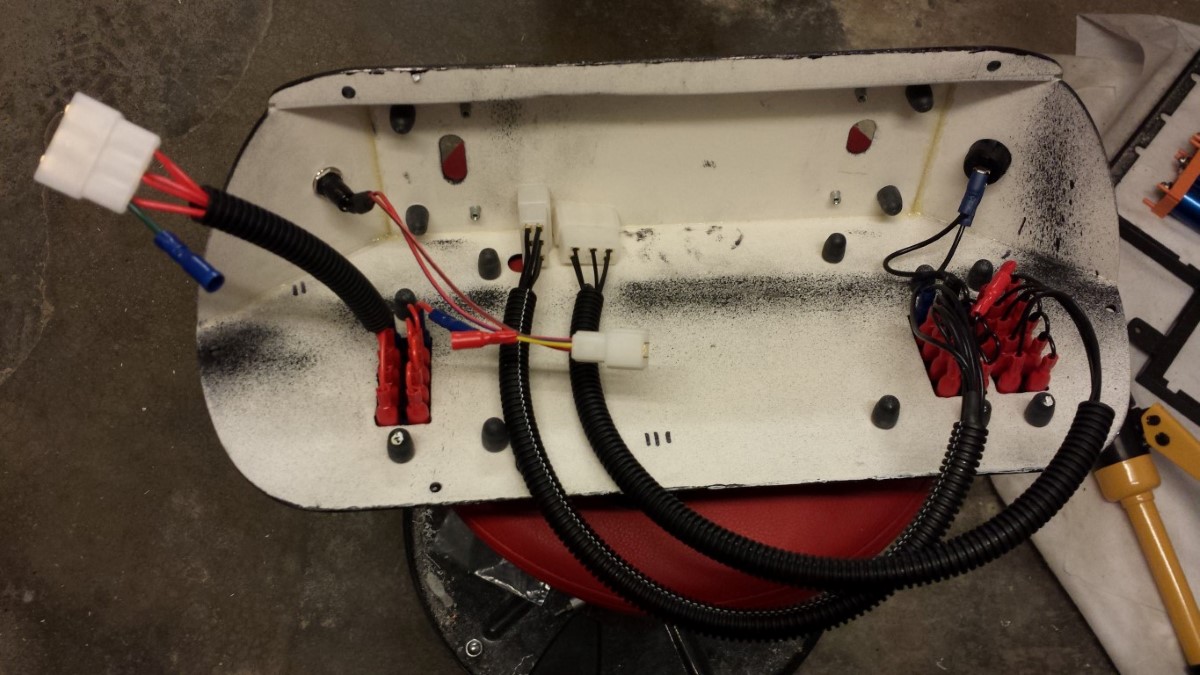

The protective covers were all sprayed black. I did this myself and it actually still turned out pretty nice.

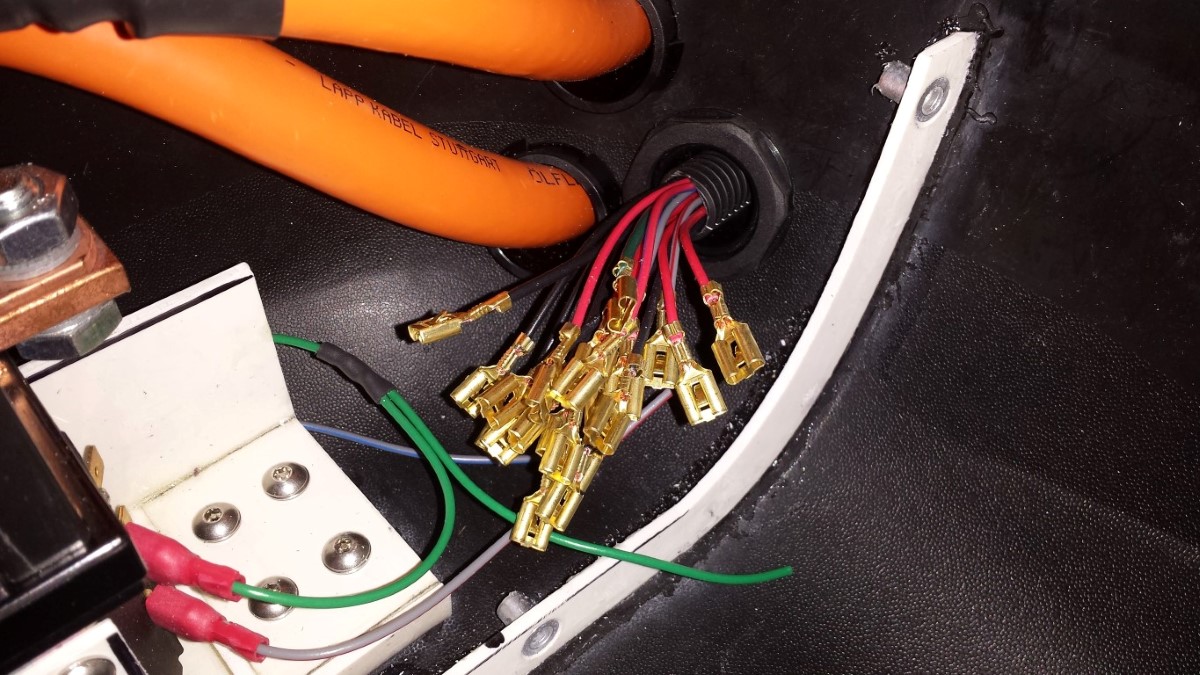

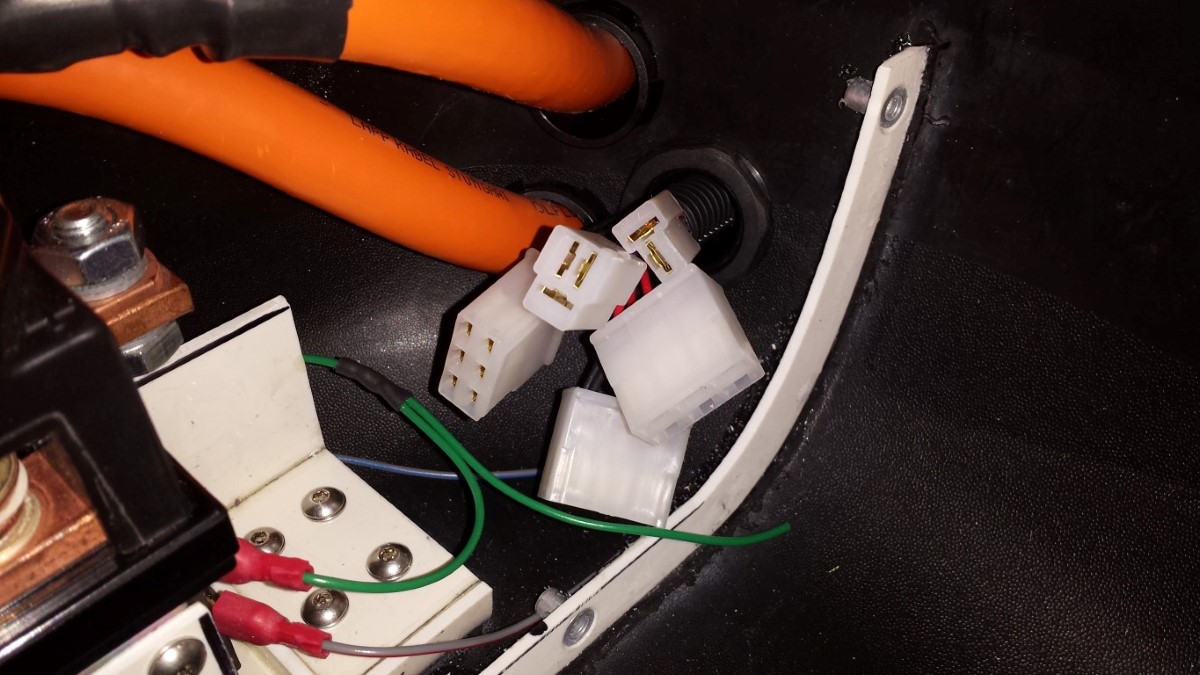

I still want to be able to detach the plates so I bought some connectors again for all of the wires. The top case itself is already waterproof so I don't need waterproof connectors for this. First I put all of the contacts on the wires.

With the connectors on.

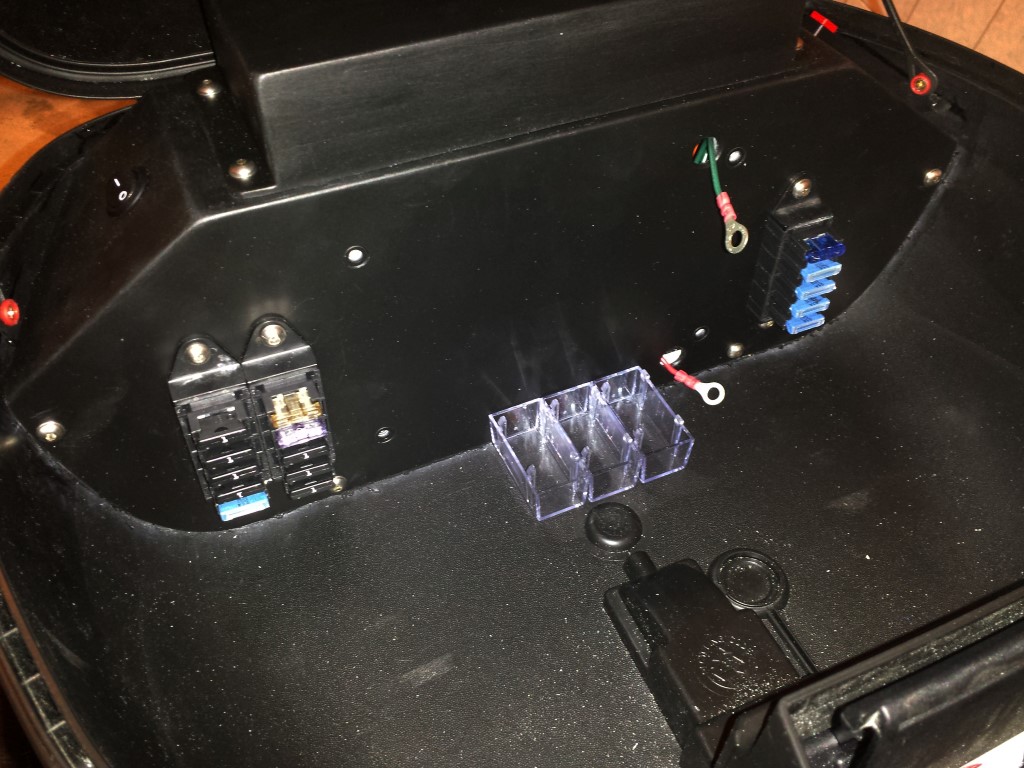

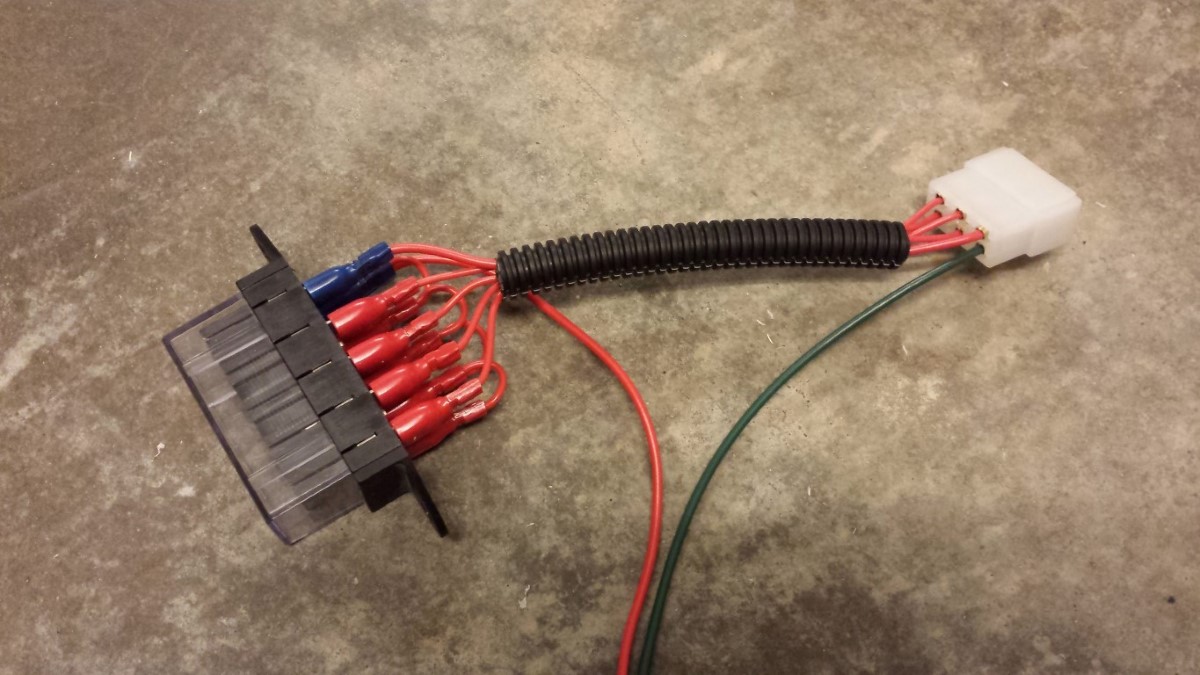

Since I made a complete new wire harness I wanted to add some extra safety. I bought a few fuse boxes which all seperate circuits are fused with. Was a lot of work to connect this all but it'll be very nice when it's in use.

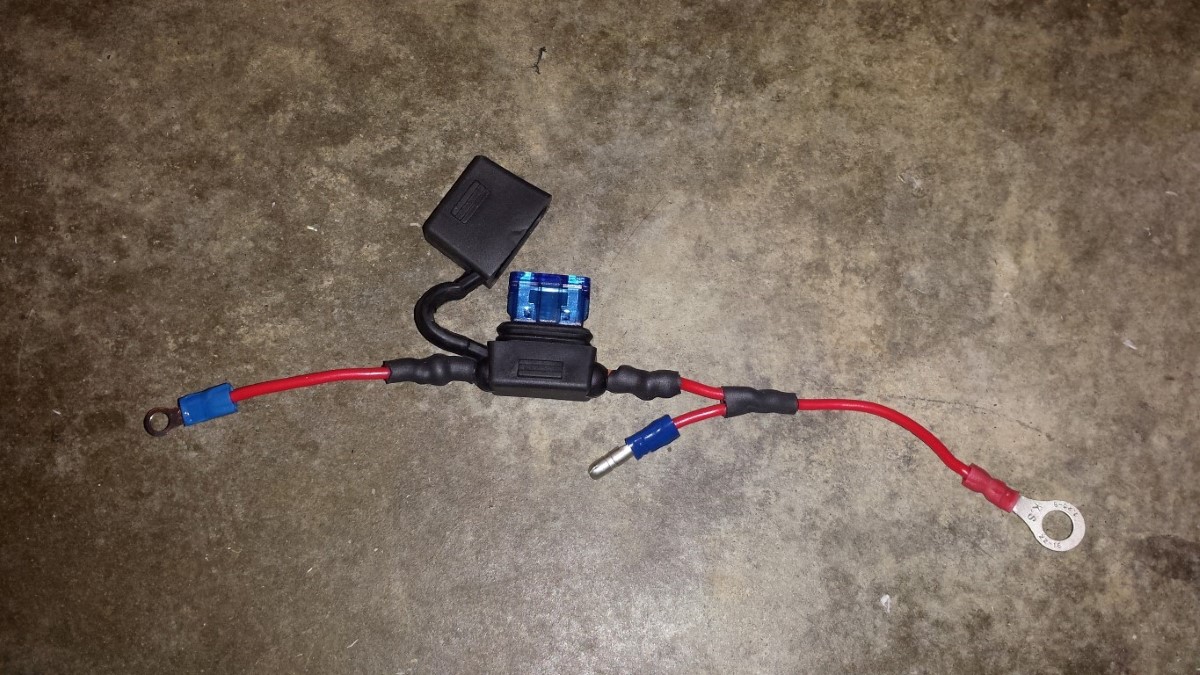

The wires between the DC-DC converter, 12V battery and wire harness were also very fun to make exactly to size. The + wire of the DC-DC converter also has a seperate fuse.

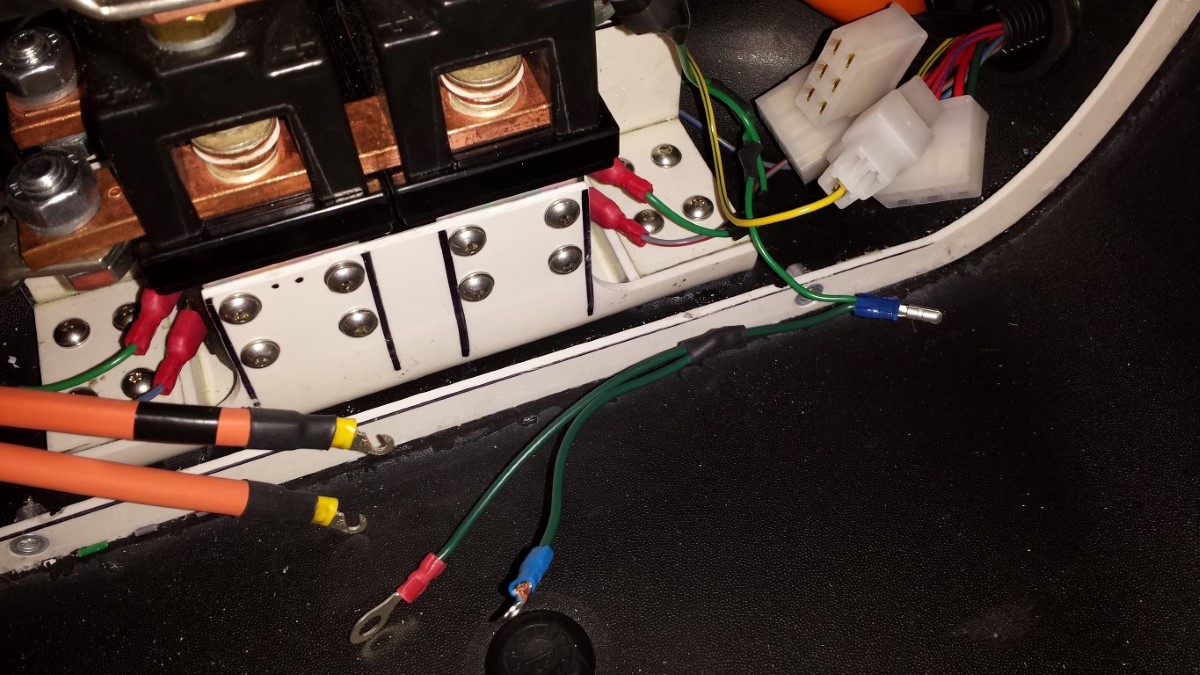

Attached everything to the protective cover. Now you know what all the holes I made in it are actually for.

Was quite some work to get everything connected before I could attach the plate but finally it looks very nice now.

DC-DC converter attached and connected.

And another protective cover on there.

The 12V battery I won't connect for now. I did this for a short moment but then I saw that the DC-DC converter actually draws a little power. So I can only connect it once I have the whole battery pack connected so the DC-DC converter can keep the 12V battery charged. That's what I'll be busy with the coming days. Will be a bit more exciting since I won't be working with 12V anymore but 72V.

Nederlands

Nederlands